A good friend of mine, Dale Lewis, has been going through a tough spell medically, so me and some friends are trying to raise some money to get him a mobility scooter through GoFundMe. Please take a moment to read Dale’s story and donate if you can. If you can’t donate, please help us spread the word. Thank you!

Over the past several months, I’ve gotten back into buying and reading comic books. One of the roadblocks that I had before was time. And that was two-fold as it takes time every week to get in the car, drive over to the local comic book store and pick up your subscriptions, then haul it all back home. As much as I want to support local businesses, I found that Midtown Comics in New York was able to ship out subscriptions monthly. So, I started getting my books through them and have had a great experience so far.

The other facet was having to find the time to read the books. I’m slowly getting better at this and hope to get caught up soon on all the books I’ve been buying over the past six months. I did get a chance to visit the local stores a bit in early May for the Free Comic Book Day event. While I did get several free books, I also took advantage of some sales that got me good discounts of trade paperbacks, back issues, and even a full set of 1990 Marvel Universe Series I cards, complete with holograms. Here’s a list of all of the cards in the set, and here’s a list of all of my comics.

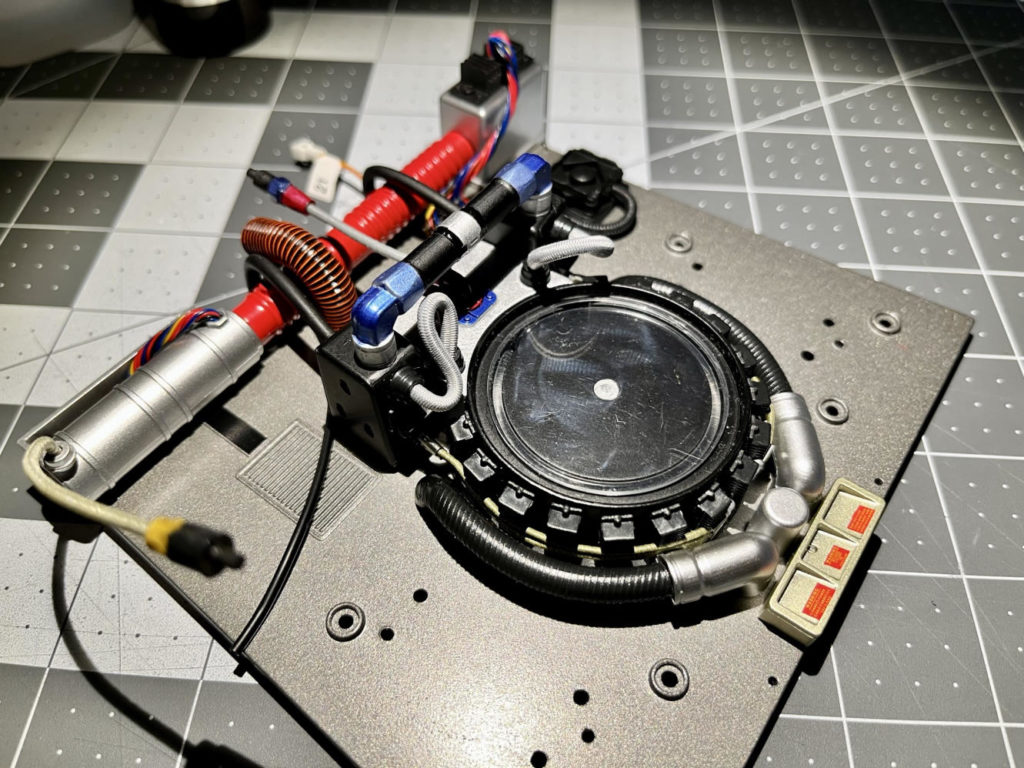

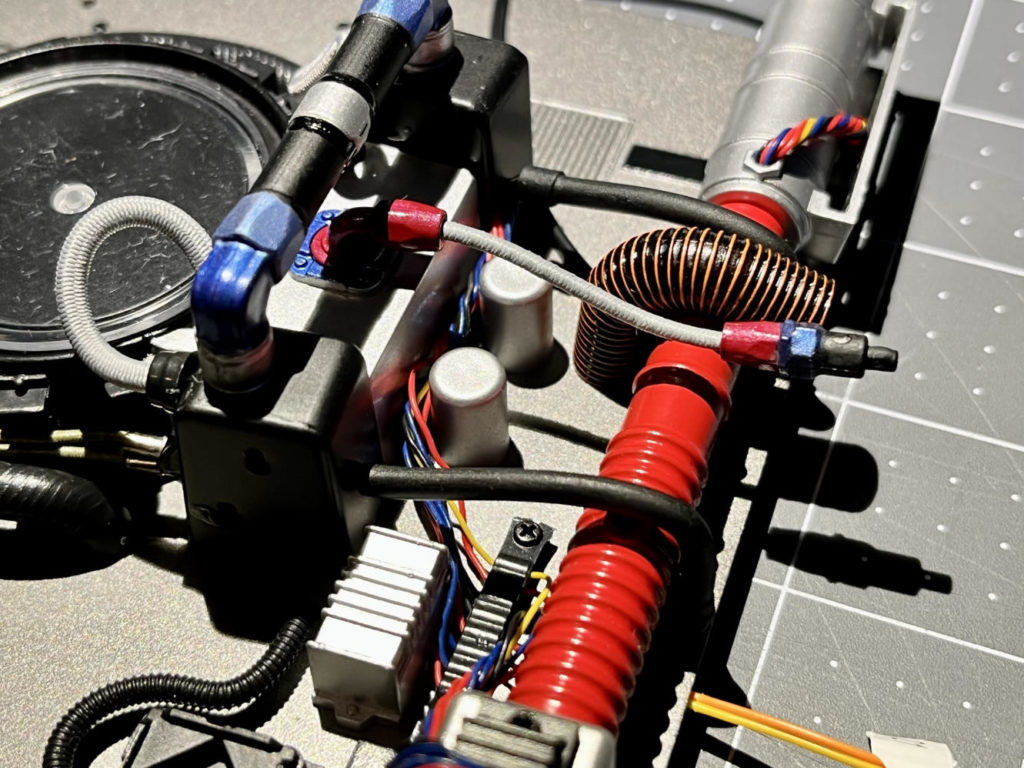

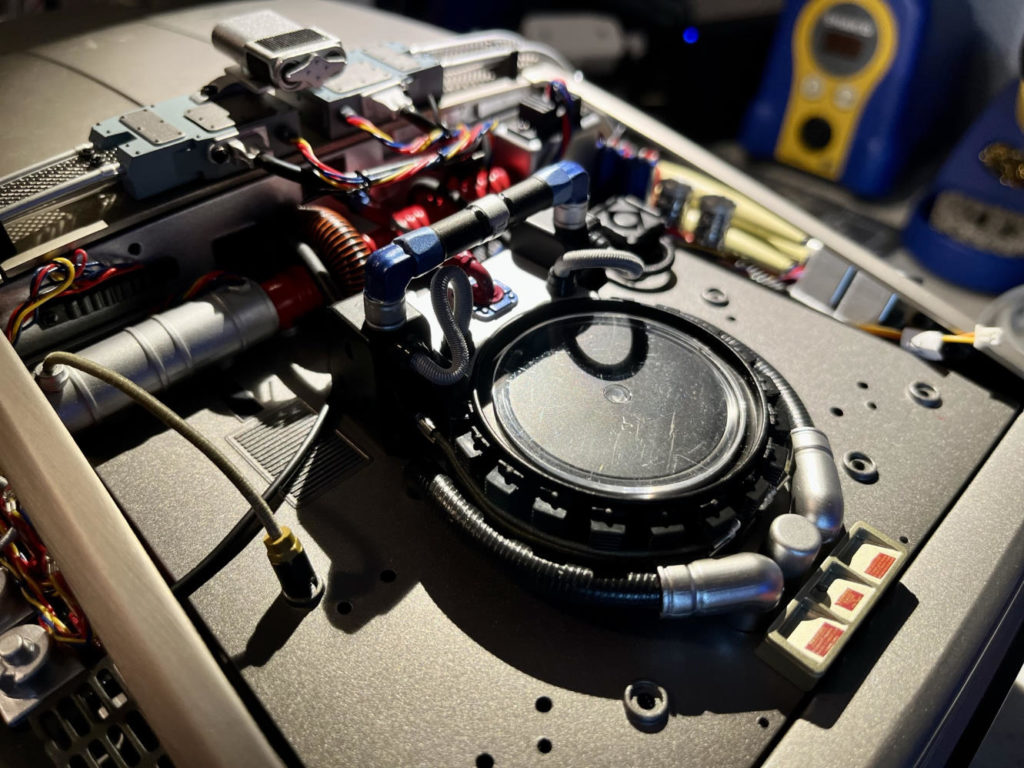

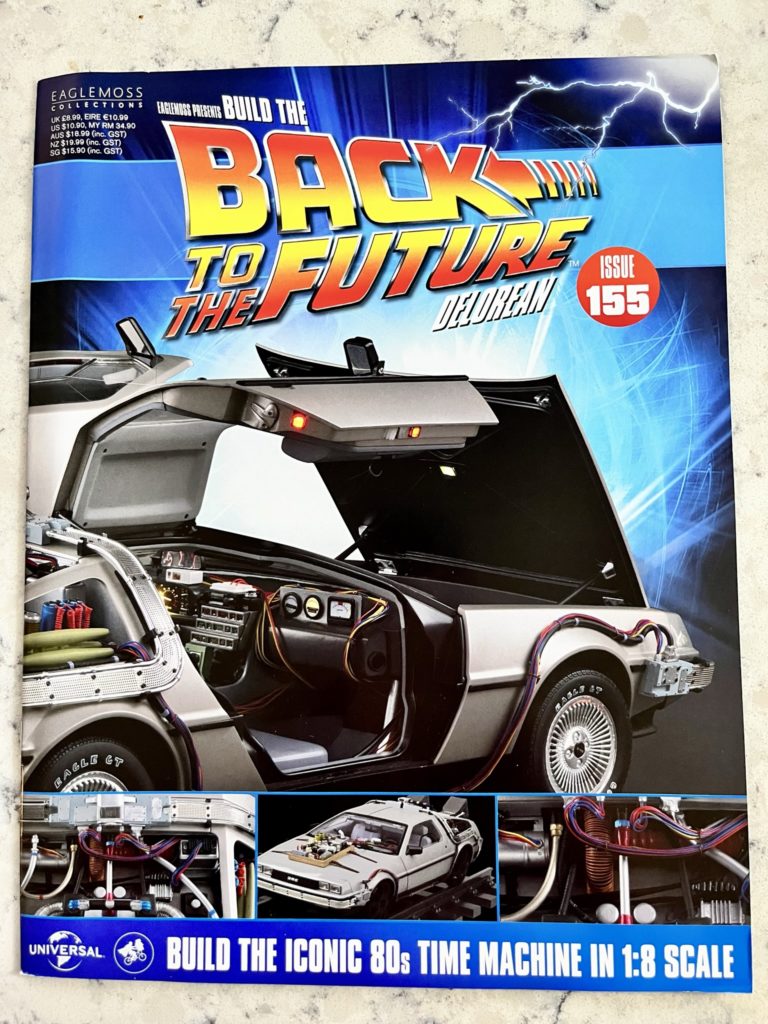

Those of you who’ve been reading these blog entries over the past couple of years know that I’ve been building a model of the DeLorean from Back to the Future. The subscription service would allow you to build out the car with a new, weekly parts kit (that were actually delivered monthly, so you’d get four kits at a time). In total, there were 159 weekly parts kits (a.k.a. Issues) that, once complete, would not only give you the famous time machine model, but also a bunch of other great little extras.

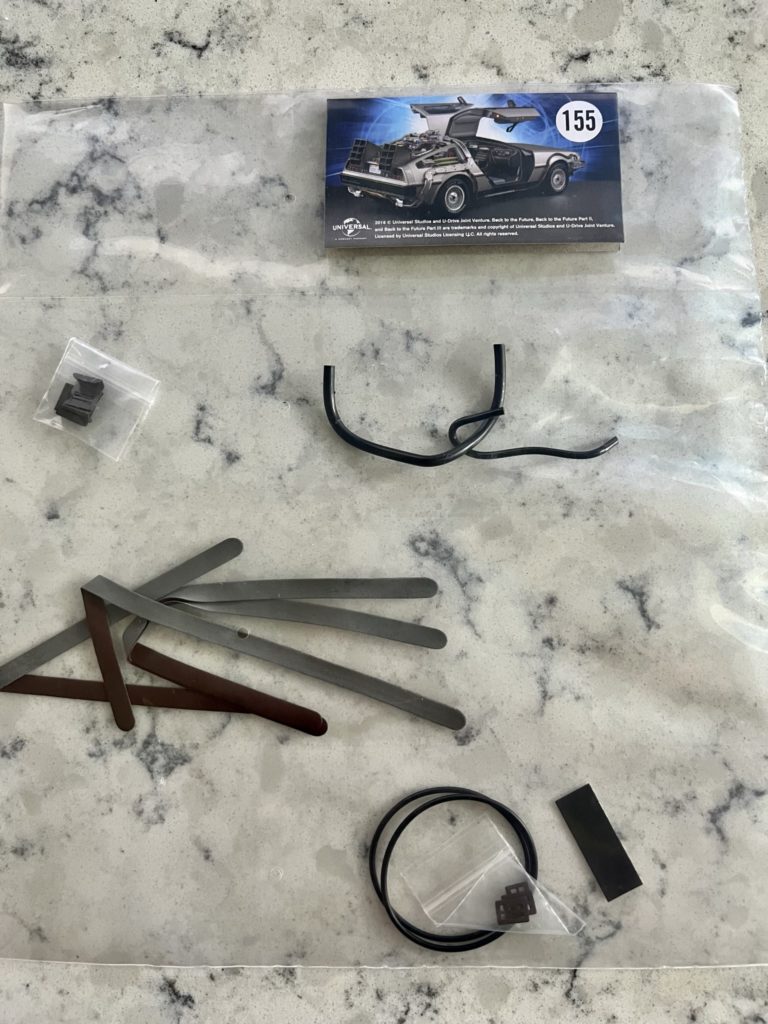

Well, back in the summer of 2022, EagleMoss, the manufacturer and distributor of the kits, files for Administration in the UK, which is akin to filing for Bankruptcy in the US. The last kit/Issue I received was 154, leaving me five kits behind. Luckily, Fanhome (De Agostini Publishing) seems to have purchased EagleMoss since last year and recently they emailed me telling me I could complete my model. Today, kit/Issue 155 showed up. Can’t wait to finish everything off.

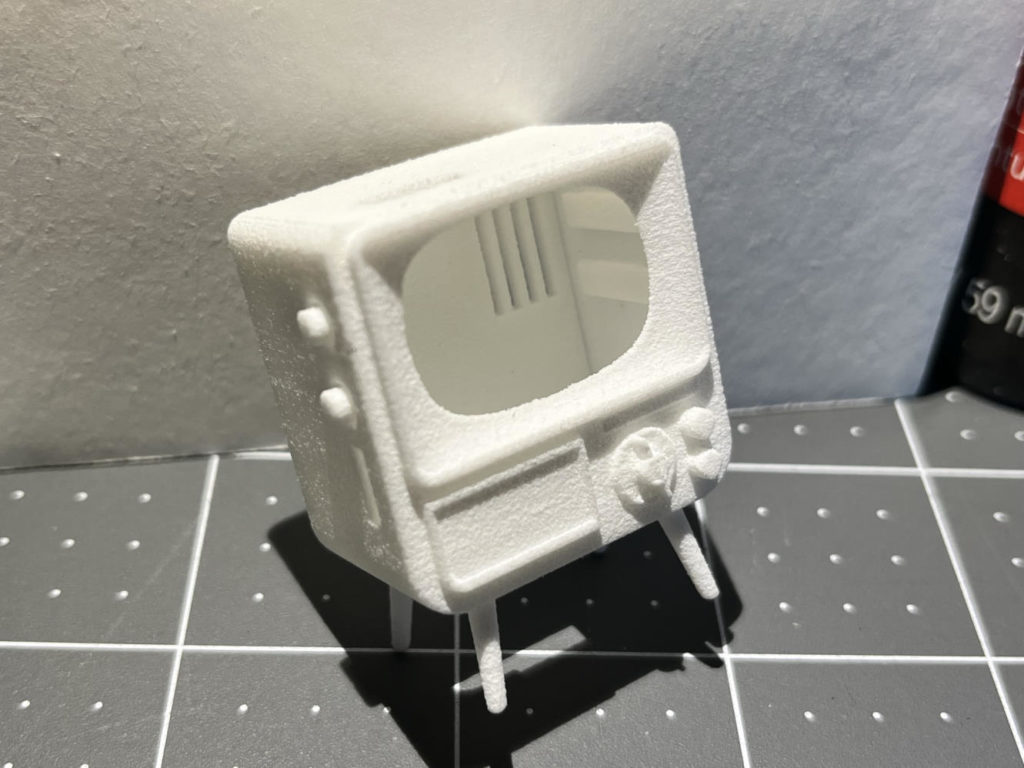

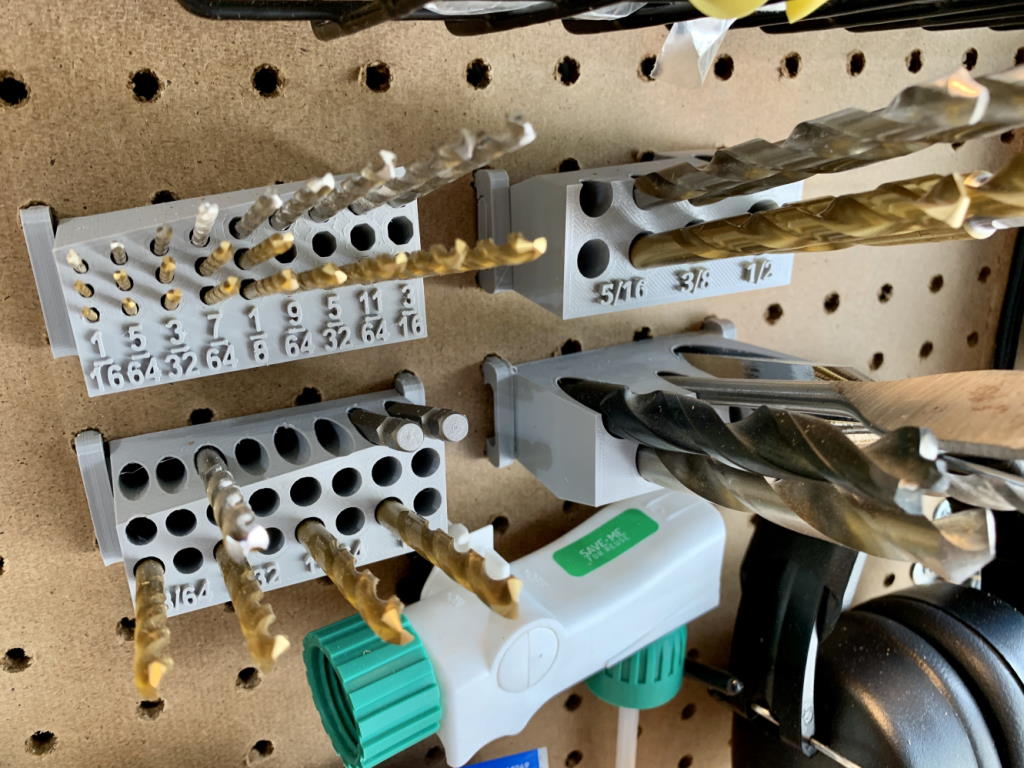

I’ve got a few minor projects to complete today, and afterward I’ll be working on getting my 3D printer up-and-running again.